Turnkey EOL Test Solutions for High-Reliability Industries and Complex Assemblies

Test Automation

Test Automation

Arxtron’s EOL systems are designed for a wide range of finished product tests, such as:

- Final functional verification (e.g., power-up, communication protocols, analog measurements).

- Software load and validation using production firmware through CAN/LIN or in system programming methods.

- Custom signal testing over communication buses (e.g., CAN, LIN I2C, SPI, Automotive Ethernet).

- Laser marking and barcode validation for traceability.

- Custom analog/digital measurements using Arxtron- custom designed PCBs.

Arxtron Technologies is a leading system integrator specializing in functional test and test automation solutions. Our expertise lies in designing, engineering, and building fully customized Automated End-of-Line (EOL) Test Systems that verify final product integrity in assembled housings before they leave the production floor.

We deliver turnkey EOL solutions—mechanical, electrical, and software—that ensure compliance, traceability, and high-quality standards for your complex assemblies. Our systems are built to meet the needs of high-mix, high-reliability industries including automotive, medical devices, industrial automation, aerospace, consumer electronics, and defense.

Capabilities & Technologies

Arxtron delivers high-performance EOL test solutions with the following capabilities

- CAN/CAN FD, LIN, SPI, I2C, UART, USB, Automotive Ethernet communication support.

- Custom PCB design for precise analog measurements.

- Fault injection and tolerance checks.

- Power and current monitoring (nominal and sleep modes).

- NI TestStand and LabWindows/CVI for test sequence automation.

- Real-time operator and production interfaces.

- SQL-based recipe and test data management.

- Data logging in various formats for local or network traceability systems.

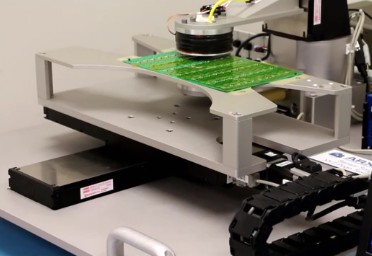

- SCARA robots/XYZ Gantry systems for pick-and-place operations.

- Pick and place grippers with dual-sensor verification.

- Integrated barcode scanners and laser etchers.

- Fully enclosed guarding with safety interlocks.

- Custom mechanical nests with presence and position sensing.

- Modular cabinet systems for instrumentation and controls.

- In-house custom PCB development for signal conditioning and measurement accuracy.